The Main Factors Causing Compatibility Problems with Concrete Admixtures: Key Influencing Elements

–The main factors causing compatibility problems with concrete admixtures

Concrete admixtures play a crucial role in enhancing concrete properties. However, compatibility issues often arise, affecting performance. Several main factors contribute to these problems, requiring careful consideration during material selection and mixing.

Chemical Composition Discrepancies

Admixtures and cement have different chemical compositions. For example, sulfonate-based superplasticizers may react with aluminum compounds in cement. Such chemical reactions can form precipitates, reducing admixture effectiveness. Manufacturers must ensure chemical compatibility between these components.

PH Value Variations

The pH level of the concrete mixture significantly impacts admixture performance. Some admixtures, like polycarboxylate ether (PCE) superplasticizers, function best in specific pH ranges. A sudden pH change due to cement type or additive inclusion can disrupt their molecular structure, leading to compatibility issues.

Mixing Sequence and Order

The order in which admixtures are added to the concrete mix matters greatly. Adding water-reducing agents before cement might cause uneven dispersion. Conversely, late addition of air-entraining agents could lead to poor bubble distribution. Proper mixing procedures are essential to avoid these problems.

Temperature Fluctuations

Environmental temperature affects chemical reactions in concrete. High temperatures speed up hydration, while low temperatures slow it down. Admixtures designed for normal temperatures may not perform well under extreme conditions, causing compatibility issues in hot or cold climates.

Admixture Type and Dosage

Different admixture types, such as accelerators, retarders, and plasticizers, have unique mechanisms. Using an incompatible type together, like a calcium chloride accelerator with certain superplasticizers, can trigger adverse reactions. Additionally, exceeding the recommended dosage often leads to performance problems instead of improvements.

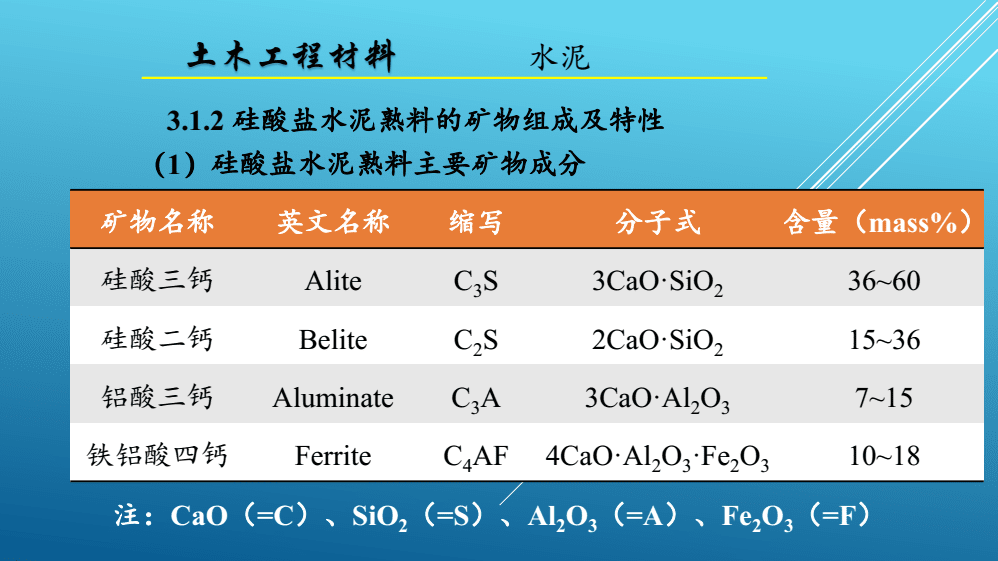

Cement Characteristics

Cement properties like fineness, mineral composition, and alkali content vary among producers. A cement with high tricalcium aluminate (C3A) content may absorb more superplasticizer, reducing its efficacy. Builders must match admixtures to the specific cement characteristics to ensure compatibility.

In conclusion, compatibility problems with concrete admixtures stem from multiple factors. Understanding chemical compositions, pH levels, mixing sequences, temperature effects, admixture types, and cement properties is vital. Proper material selection, testing, and application procedures can significantly reduce these issues, ensuring high-quality concrete production.